Services Offered

Laboratory Tests

The Mine Design Lab offers a wide range of laboratory testing services to industry through its Rockbolting Laboratory. The lab is equipped with a 2 MN servo press by CONTROLS and two Hoek’s triaxial cells (NQ and 2-inch diameter). Rock cores are completely prepared in-house using our rock cutting and measurement tools in accordance with ASTM standards. If needed, samples can be instrumented with strain gauges and LVDT to determine the modulus of elasticity and the Poisson’s ratio in the uniaxial compressive strength (UCS) test.

2 MN Servo-controlled press run by AUTOMAX

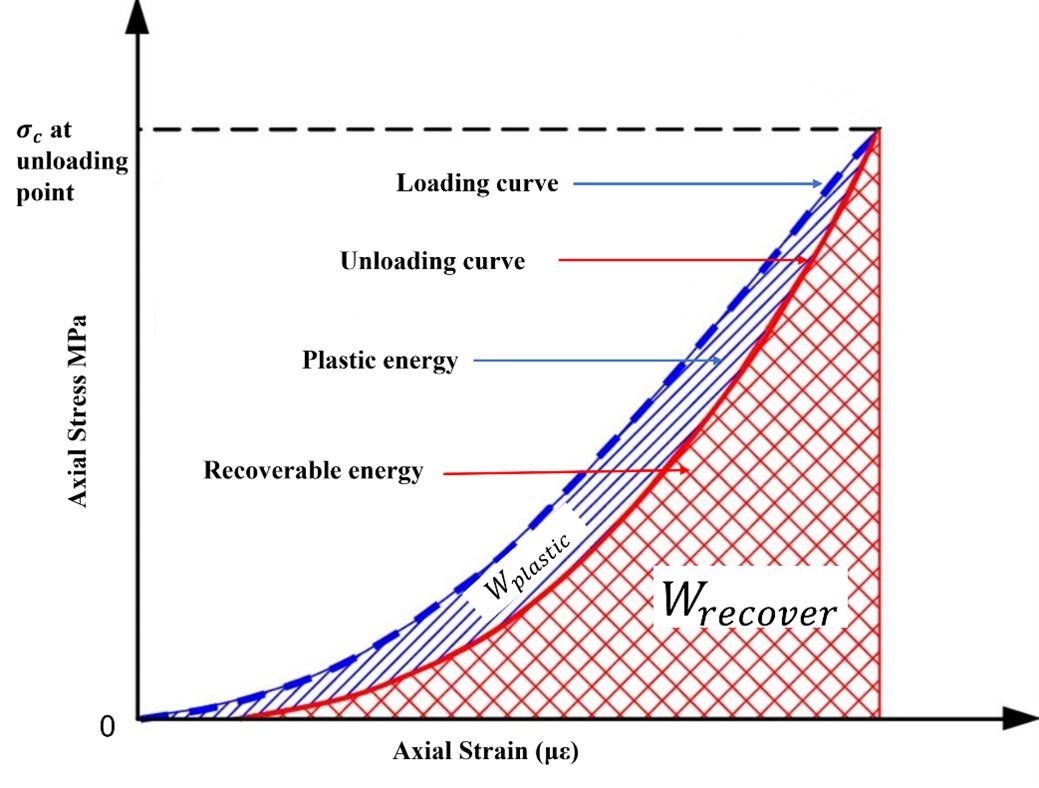

Rock tests include UCS, load-unload (LUN) tests, triaxial compressive strength, and Brazilian Tensile Strength. The LUN tests are used to determine rock burstability potential View article. The figure below illustrates the LUN procedure.

Load-unload (LUN) test for rock burstability evaluation

We have recently developed a novel method for the determination of the direct tensile strength using expansive cement known as the ECDTS (View article). The method is based on coring a central hole in an instrumented cylindrical sample and filling it with expansive cement; see illustration below.

The ECDTS setup

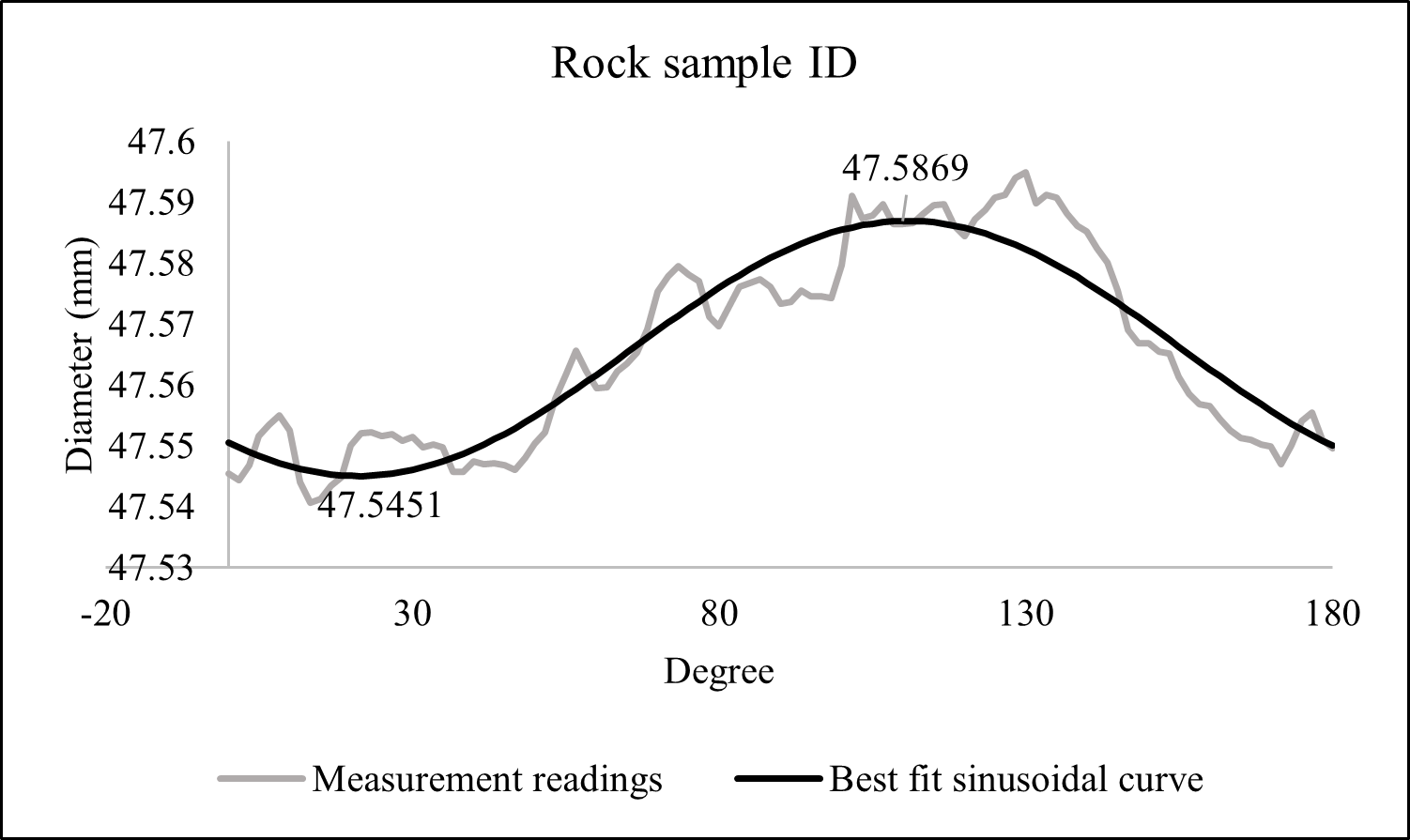

The diametric core deformation technique (DCDT) estimates the difference between the two local principal stresses acting on a rock core. By measuring the diametric deformations of the rock core, the method calculates the differential local principal stresses. Core deformations are measured with a high precision laser equipment, shown below.

Apparatus of rock core diameter measurement

Measurement results of diametrical core deformation

For more information on the DCDT method, (View article). It explains a stepwise procedure to estimate near field in-situ stresses.

Technical Services and Training

The Mine Design Lab offers technical services to industry, particularly in rock mechanics using advanced tools of numerical modelling. Services include rock support design and back analysis, stope design and unplanned ore dilution, sill and crown pillar design, root cause analysis of mining-induced seismicity, optimized stope sequence, fill strength requirements, rockburst control with destress blasting, and rock slope stability. Services in mining practice include rock breakage without explosives, practice guidelines, and elements of mine services and materials handling design.

The Mine Design Lab offers hands-on short courses in rock mechanics focused on numerical modelling applications for underground mining using state of the art tools such as Itasca’s and Rocscience’s software tools. Courses are offered in-house but requests for onsite training can be accommodated.